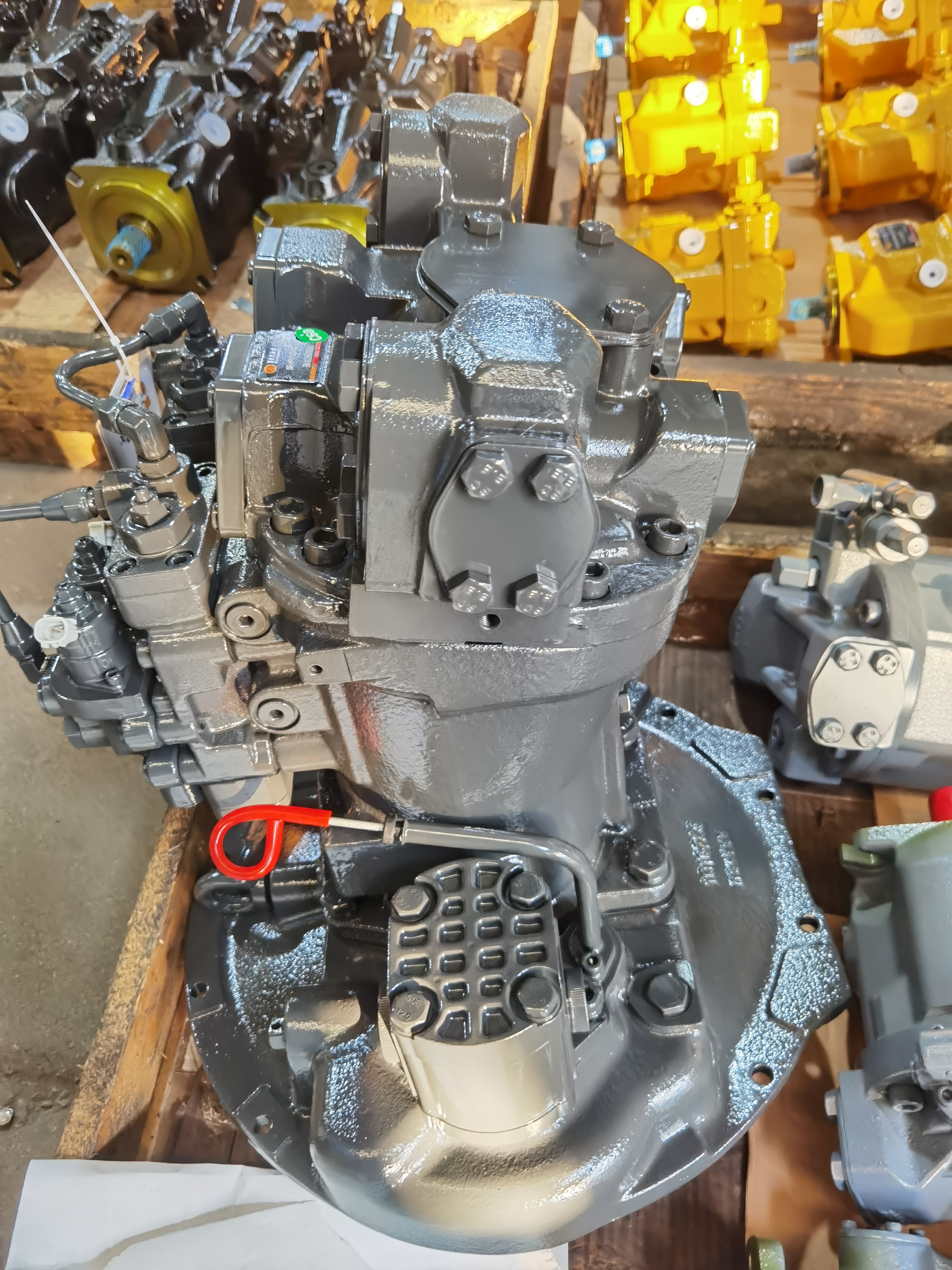

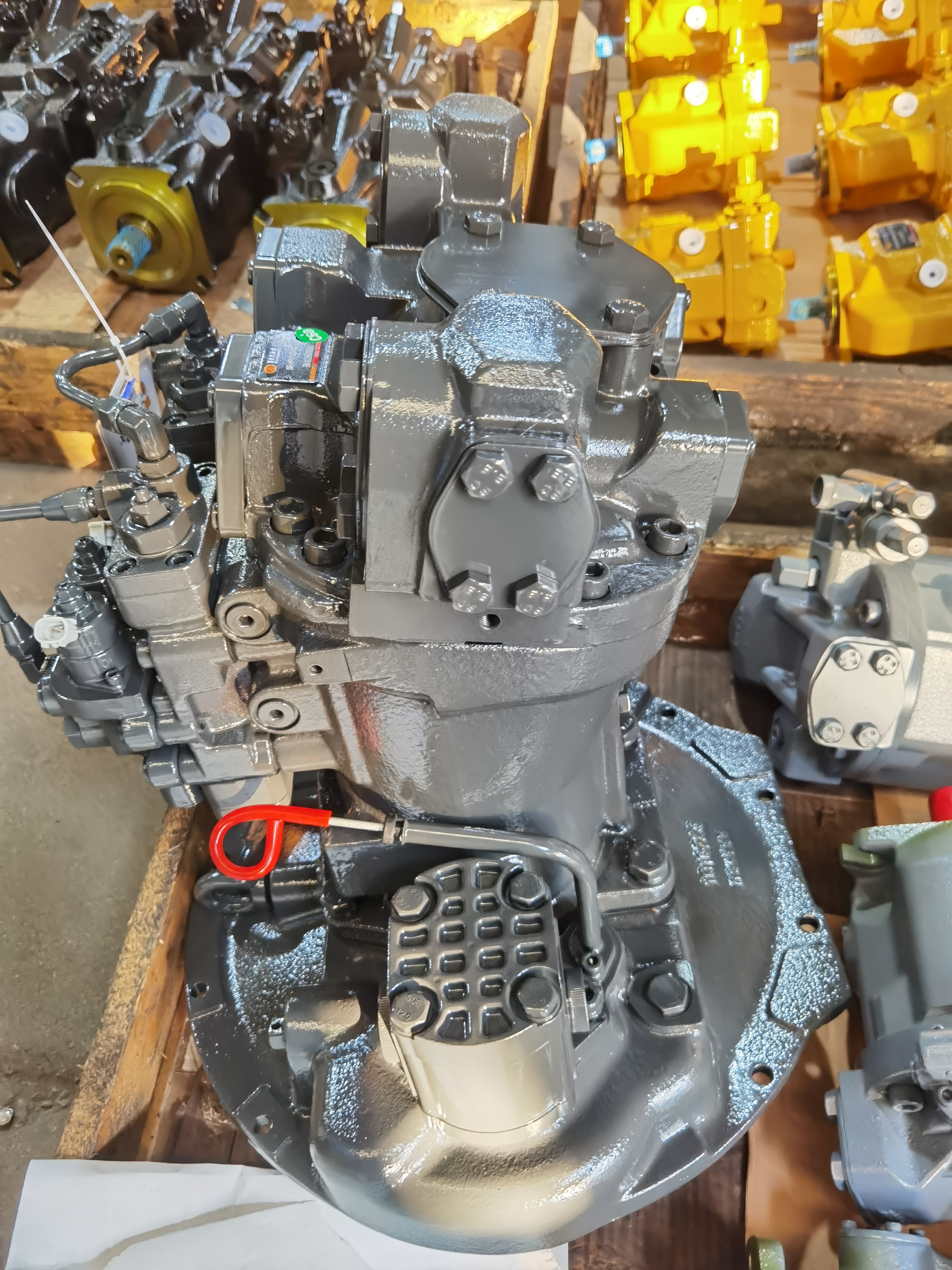

HPV102 hydraulic pump , we can supply genuine pump assy , we also have handok brand or Chinese brand , It can fit in excavator ZAXIS200; ZAXIS200-E; ZAXIS200LC; ZAXIS200LC-E; ZAXIS210H; ZAXIS210LCH; ZAXIS210K; ZAXIS210LCK; ZAXIS200-X; ZAXIS200LC-X; ZAXIS210; ZAXIS210LC; ZAXIS210N; ZAXIS240.

We have the following brands of pumps:

We have China brand / Handok brand / Kawasaki / KYB / Uchida / Genuine Hydraulic Pump , anyway will try our best to find the brand you need

The maintenance cycle and plan of hydraulic pumps are essential to ensure the normal operation of equipment and extend its service life. Here are some recommended maintenance cycles and plans:

1. Daily inspection: Before each use, check whether the hydraulic pump is installed accurately and reliably, whether the pump body is filled with oil, whether the pump direction is consistent with the inlet and outlet ports, and whether the safety valve of the hydraulic system is adjusted to the specified pressure value.

2. Replacement of hydraulic oil: It is recommended to replace the hydraulic oil after 500 hours of initial operation. The maximum cycle of hydraulic oil replacement is 2000 hours. If the hydraulic system is equipped with an air filter, the maximum replacement cycle is 500 hours.

3. Regularly check the quality of hydraulic oil: The oil quality should be sampled and tested regularly. If the oil quality does not meet the use requirements, it must be replaced. At the same time, pay attention to the operating temperature of the hydraulic oil should not exceed 80℃, and it is generally controlled within the range of 35~70℃.

4. Inspection and replacement of filter element: Detection and replacement of hydraulic oil filter element is an essential step. It is recommended to check the condition of the filter element regularly and clean or replace it in time according to its degree of contamination.

5. Check the seals and connections: Pay attention to check the seals and connections of the plunger pump to ensure that there is no oil leakage. If leakage is found, the seals should be replaced in time.

6. Check the return oil pipeline: Check the return oil pipeline of the pump regularly to ensure that there is no blockage and damage, and ensure the smooth return of the hydraulic oil.

7. Check before starting: Before each start-up, check whether the bolts of each connection are tightened, whether the pressure gauge of the hydraulic system is normal, etc., to ensure that the equipment will not be shut down due to minor faults during use.

8. Check under special circumstances: If the pump is not used for a long time, the oil in the pump should be drained and filled with oil with a low acid value. Anti-rust oil should be applied to the exposed processing surface, and each oil port should be sealed with a screw plug to prevent dirt from entering.

By following these maintenance cycles and plans, the operating efficiency of the hydraulic pump can be significantly improved and the operating costs can be reduced.

Bolin Machinery--Professional hydraulic pump manufacturer.