Introducing the CAT Challenger 65/75/85/95 Rubber Track, designed to provide superior performance and protection for your agricultural machinery. These rubber tracks are engineered with a low ground pressure ratio, ensuring minimal soil compaction and maximum soil protection during operation.

The CAT Challenger 65/75/85/95 Rubber Track is specifically designed to reduce the impact on the soil, making it ideal for use in sensitive agricultural environments. With a focus on sustainability and efficiency, these rubber tracks help preserve the integrity of the soil while enhancing the overall performance of your machinery.

Constructed with high-quality materials and advanced technology, the CAT Challenger 65/75/85/95 Rubber Track offers durability, reliability, and long-lasting performance. Whether you are working in challenging terrain or delicate soil conditions, these rubber tracks provide the traction and stability needed to get the job done efficiently and effectively.

Application Models for Caterpillar Tractor

|

| Challenger 65B | Challenger 65C | Challenger 65D | Challenger 65E | Challenger 70C | Challenger 75C | Challenger 75D |

| Challenger 75E | Challenger 85C | Challenger 85D | Challenger 85E | Challenger 95E |

|

|

Related Part Number:

652-2506 , 632-2529 , 622-2515 , 652-3004 , 652-3055 , 652-3049 , 652-3052 ,

F30AL02918 , 632-3048 , 632-3057 , 622-3007 , 616530 , 703616530

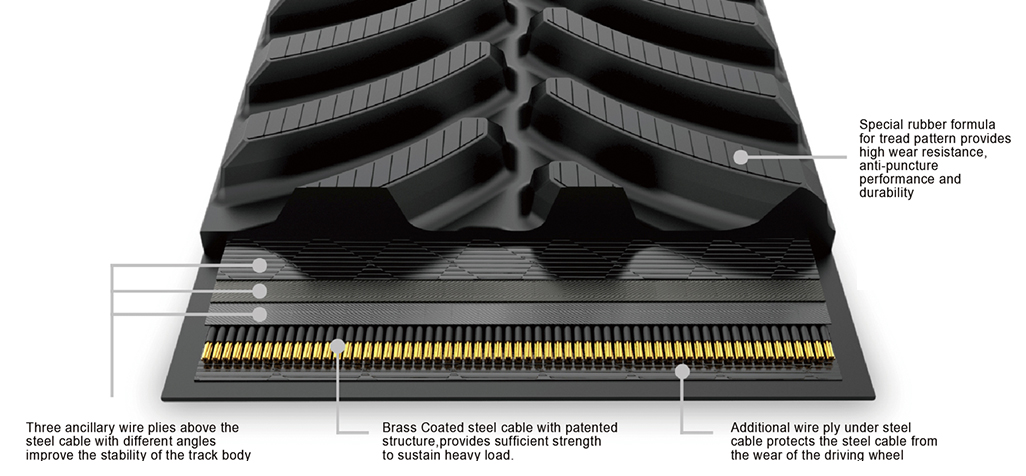

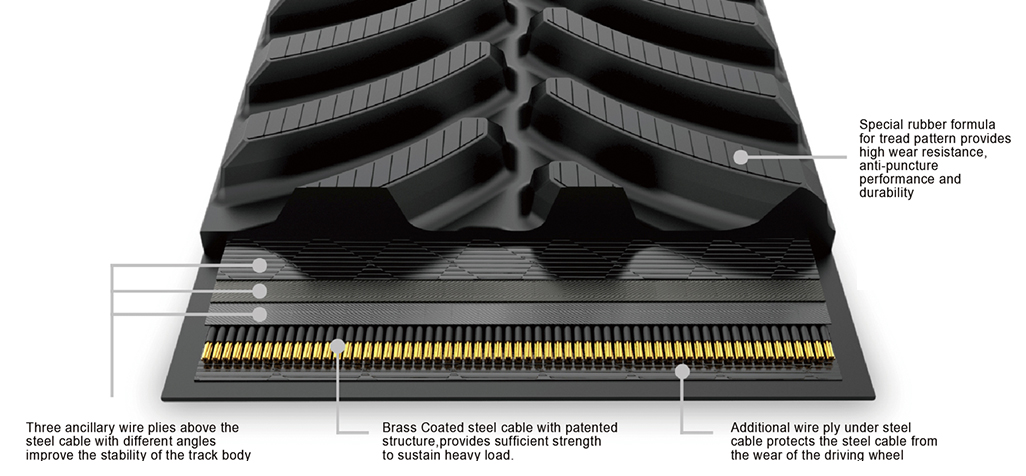

Product Display:

The replacement cycle of rubber tracks is affected by the frequency of use. The higher the frequency of use, the greater the wear of the rubber tracks, thus shortening their service life. To determine whether the rubber tracks need to be replaced, you can refer to the following aspects:

1. Degree of wear: Check the wear of the rubber tracks. If the wear is severe, such as cracks, cuts or rubber shedding, it may need to be replaced.

2. Use time: Rubber tracks usually need to be replaced after 1-2 years of use, but the specific time also depends on the use and maintenance.

3. Performance degradation: If the performance of the rubber track is significantly reduced, such as reduced traction or unstable walking, this may be a signal for replacement.

4. Regular inspection: Regularly check the rubber tracks, including tightness, whether there are foreign objects embedded, and the wear of auxiliary parts.

In addition, the maintenance of rubber tracks is also very important. Proper use and maintenance can extend their service life. For example, avoiding use under harsh road conditions, regularly cleaning rubber tracks, and avoiding contact with chemicals and oils can all help maintain the performance of rubber tracks and extend their service life.